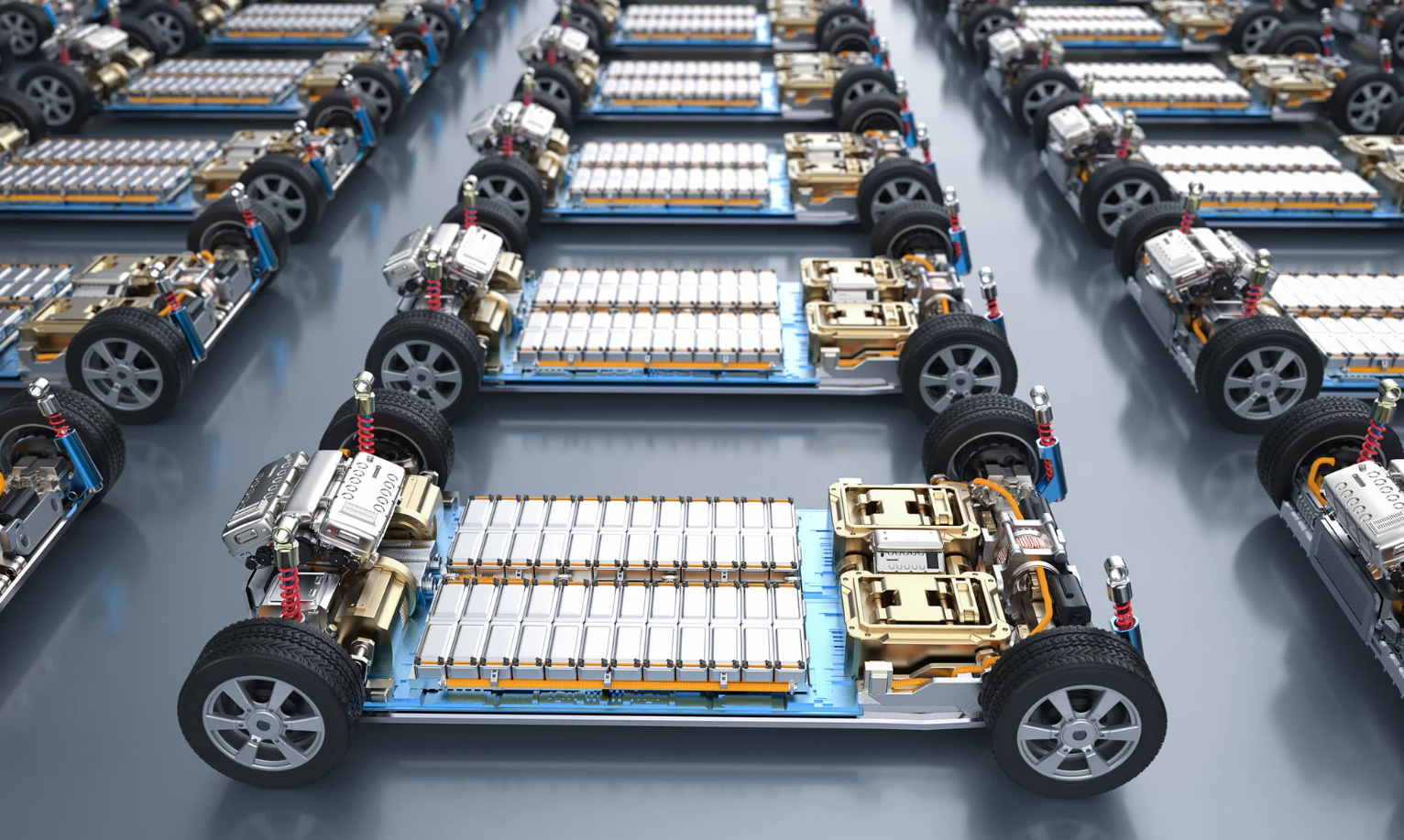

Samangan CRT Technologies has

introduced groundbreaking products poised to revolutionize the automotive

industry. Its innovative lightweight automotive components, incorporating cenospheres

derived from fly ash, which is readily available from power plants, have

represented a cutting-edge solution designed to significantly improve fuel

efficiency, minimize environmental impact, and elevate overall performance. By

emphasizing seamless integration into existing manufacturing processes, the

company has also minimized disruptions and allowed for a smooth transition to

cenosphere-infused components. This forward-thinking approach has aligned

seamlessly with the growing demand for sustainable and eco-friendly practices

within the automotive sector. In addition, the introduction of advanced eco-friendly surface coatings

such as ceramic, epoxy-based or sol-gel formulations has further enhanced

product durability by improving thermal resistance and corrosion protection,

particularly in high-stress environments like engine bays and underbodies. This

added layer of protection ensures longer component lifespan and reliable

performance under extreme operating conditions. Moreover, the outlined strategies

for cost-efficiency optimization, coupled with longterm savings through fuel

efficiency gains, have made this concept a compelling and comprehensive

solution that meets industry demands for lightweight, sustainable, and

cost-effective automotive materials.Samangan CRT Technologies has

introduced groundbreaking products poised to revolutionize the automotive

industry. Its innovative lightweight automotive components, incorporating cenospheres

derived from fly ash, which is readily available from power plants, have

represented a cutting-edge solution designed to significantly improve fuel

efficiency, minimize environmental impact, and elevate overall performance. By

emphasizing seamless integration into existing manufacturing processes, the

company has also minimized disruptions and allowed for a smooth transition to

cenosphere-infused components. This forward-thinking approach has aligned

seamlessly with the growing demand for sustainable and eco-friendly practices

within the automotive sector. In addition, the introduction of advanced eco-friendly surface coatings

such as ceramic, epoxy-based or sol-gel formulations has further enhanced

product durability by improving thermal resistance and corrosion protection,

particularly in high-stress environments like engine bays and underbodies. This

added layer of protection ensures longer component lifespan and reliable

performance under extreme operating conditions. Moreover, the outlined strategies

for cost-efficiency optimization, coupled with longterm savings through fuel

efficiency gains, have made this concept a compelling and comprehensive

solution that meets industry demands for lightweight, sustainable, and

cost-effective automotive materials.